Grinding Ball Mills production of General Machinery for sale. - Agavia

Thursday, 3 August 2017Item details

City:

Agavia, Gauteng

Offer type:

Sell

Item description

About General&Hafa Raymond Mills designing always is regenerated and this process is reflected to our designs. General & Hafa Pendulum mills are used in a wide range of industrial fields. As construction, chemicals, chemical fertilizer production, metellurj, mineral, ceramic, steel, thermal power, bricks and tiles, the coal industry. The humidity is below 6%, it can grind these materials which are not explosion and flames. There are thousands of varieties can grind materials. Typically; cement, quartz, feldspar, gypsum, limestone, dolomite, graphite, fluorite, phosphate ore, ferro-manganese, coal, slag, granite, marble, barite, such as ceramics and glass.

At the Raymond Mill, the most common problem is not to be done function because of pendulum balls failure. Through innovation, who brought to pendulum ball lubrication and dust tightness, reliable and has low maintenance cost production can be make. Mill main bearing system is designed to be dust sealed. If system is used according to operation instructions it can be give over 25 years.

Integrated dynamic separator is placed in the mill. The milled material grain size can be obtained at one time so that the fineness of the desired material limiting. Different dynamic separator designs are available according to the different material properties and grain size analysis on request. The most suitable design is choose for operation process by us .The separators are equipped with a standard leak prevention system.

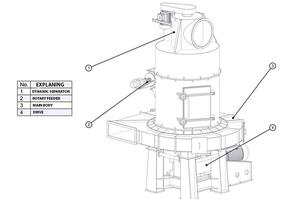

Gmhfs series mill consists of the following components;

- Feed Unit: Small-grained bulk material has been specifically designed to be fed smoothly.

- Drive Unit: The unit is where the main motor , the gearbox and couplings. Coupling design and production is belong to our company.

- Main Body: The unit is where the milling process takes place. Air intake and distribution takes place here.

- Dynamic Seperator: It is part of the particle size is classified. Adjustable rotor speed is reached at one time with the required material subtlety.

At the Raymond Mill, the most common problem is not to be done function because of pendulum balls failure. Through innovation, who brought to pendulum ball lubrication and dust tightness, reliable and has low maintenance cost production can be make. Mill main bearing system is designed to be dust sealed. If system is used according to operation instructions it can be give over 25 years.

Integrated dynamic separator is placed in the mill. The milled material grain size can be obtained at one time so that the fineness of the desired material limiting. Different dynamic separator designs are available according to the different material properties and grain size analysis on request. The most suitable design is choose for operation process by us .The separators are equipped with a standard leak prevention system.

Gmhfs series mill consists of the following components;

- Feed Unit: Small-grained bulk material has been specifically designed to be fed smoothly.

- Drive Unit: The unit is where the main motor , the gearbox and couplings. Coupling design and production is belong to our company.

- Main Body: The unit is where the milling process takes place. Air intake and distribution takes place here.

- Dynamic Seperator: It is part of the particle size is classified. Adjustable rotor speed is reached at one time with the required material subtlety.